I was working on my 1994 Jeep Grand Cherokee today. Just changing oil and replacing an upper radiator hose. I put my hand on my cruise control module and leaned a bit too hard on it – “SNAP”. I broke off the vacuum nipple at the base of the plastic molded housing. That’s the end of that! Well, my cruise hasn’t work for over 10 years so I wasn’t too sad. I thought I might as well do an autopsy to see how it worked and if it didn’t work then what went wrong so long ago.

Here is the full module with vacuum diaphragm canister control and throttle cable.

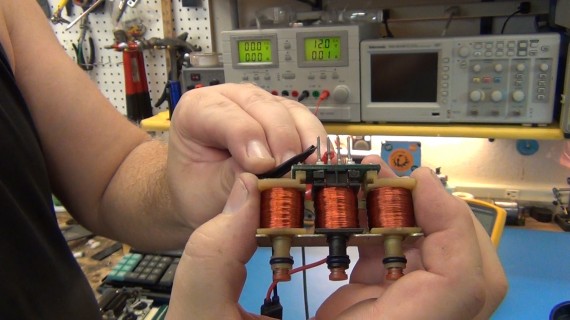

Below are the control solenoids that dial in just the right vacuum to pull the diaphragm and throttle cable back to a selected cursing speed.

CLICK TO READ ALL —>:

The inside of the vacuum chamber which has a diaphragm return spring.

The diaphragm with the throttle cable connector in the middle.

The three solenoids each control the bleed vacuum through three different sized holes.

The control solenoids simply pull out of the plastic case. They have rubber stoppers on the tips and o-ring seals.

The PCB with only one fly back diode used for the solenoid that controls the largest bleed hole. The engineers must not have been concerned with fly back on the other two solenoids. Just guessing, maybe because the other two only engage ever so shortly. This is wired as a common anode control.

In the video I setup experiments to test each solenoid using my bench supply. Each worked just fine so my problem with my cruise for the past 10 years is under the dash. I really don’t care to fix it because I never use cruise.

Thanks for joining.