Fun Stuff

Spoiler: This hack didn’t work! But the 2nd build did work! Click to see working Bazooka Halloween Fog Machine

I wanted to convert my commercial fog machine that fills a room with a fine fog but can’t be used outdoors into a spooky low ground fog machine. I have seen others on YouTube do this with dry ice. I wanted to do it with just a bucket of normal ice with maybe salt water mix to chill the 200 degree C smoke that comes out of my machine. Then the smoke should hang low to the ground in our outdoor Halloween graveyard.

This is my fog machine.

My idea was to pipe the fog into this coil in a bucket.

Add some ice.

Add some salt water so the mix will help keep the coils real cold.

Hook up the fog machine to the chiller and let the cold smoke start lofting out from under the plastic sheet taped to the garage floor.

FAIL!!! All that happen is I chilled my fog back down into a liquid and then plugged up the coil.

I tried a shorter loop.

Nope!! It too just spat out fog liquid.

In the end of the video I explain my failure and how the others on the internet using a fog machine like mine and got it to work. The hot fog is just warming their dry ice they have in a bucket and the dry ice fog is what you see coming out the other side of their rigs. You don’t need a fog machine to make that work, just a blower, box of dry ice and something to warm the dry ice. I guess it works but not the way I thought it was working. Here is a link to a hack where somebody used a similar fog machine and a box of dry ice. YouTube link: Low Fog Machine – Ground Fogger

But really if you’re going to use dry ice than just do like Kipkay did and build a Mighty Mini Fog Maker because that is all you are really doing anyway. Just heating dry ice and blowing it out a hose.

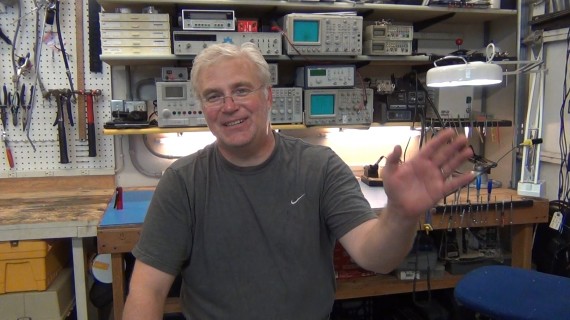

Thanks for joining and remember to subscribe to my YouTube channel and my ToddFun.com RSS feed.

I show how I replaced my broken garage door spring. This is VERY DANGEROUS so don’t try this yourself! You could kill yourself if you do something wrong. The spring is loaded with energy when in the down position and thus assists the garage door motor when opening. The weight of the door will load the spring when closing. Without a lift spring the motor either couldn’t lift the door or would burn up trying.

My door was made by Wayne-Dalton and they cut and sell the new torsion springs right at their Tempe, AZ store where I got mine.

Wayne-Dalton Residential Garage Doors 402 West Geneva Drive Tempe (480) 966-4577 http://www.wayne-dalton.com/index.html

Each spring cost $75 and are made from long life cycle spring stock not the junk spring stock the contractors quote you for their bottom line repair price over the phone. The springs are sized, cut and matched, if more than one, to your door so that the loading equation is always the same. One full spring rotation for each foot the door is high. Easy-peasy-lemon-squeezy

Not much more to add here so just watch the video for all the details.

These are my two new torsion springs with end cones ready to go on the winding bar.

When the spring broke I unplugged the motor so that step was already done. Below is the lift bar that connects the door to the lift motor gear and has to be removed during installation.

Before putting up the winding bar I check the end bearings.

This step would be easier with two people but one person can put up the winding bar.

Here I’m putting on the lift cable to the cable roller.

After attaching the cables to both cable rollers I take all the slack out of the cable and clamp the cable rollers to the brackets. Then tighten the cable roller set screws to the winding bar. Just a note: I don’t clamp the roller hard, just enough to keep it from moving until I started loading the springs.

Here I’m attaching the torsion springs to the spring anchor in the middle of the garage door. This anchor bracket needs to be bolted solid to the wall because the springs apply all their torque to this anchor and you don’t want it ripping out of the wall. If it did it would spin like a saw blade hacking up anything to close.

Scroll through the next few photos to get an idea how I use these large roller pins to load the springs. After loading with 7 rotations I tighten up the set screws on the spring cones. I counted 7 rotations because my door is 7 feet high but I could have just counted the swirl lines being these new springs had a white line down one side. Older springs don’t have this line but you could add it yourself I guess.

I removed my C-clamps.

Attached my lift bar.

Plug the motor in.

And it is working again!

Thanks for joining and remember to subscribe to my YouTube channel and my ToddFun.com RSS feed.

bye!

In this video I rebuild my Craftsman oil free air compressor for ~$47 USD. This is a ~12 year old compressor that could no longer get up to pressure and would have cost over $350 to replace. Well that was the cost over 12 years ago. I couldn’t find a 5 HP 30 gal model like this on the market anymore. The only 5HP models were over $1000 and more gallons.

You can also find another good Craftsman air compressor rebuild video of a smaller model here: http://www.youtube.com/watch?v=zUw7r0fJqIc

My compressor is a 5HP 30gal model 919-165300 and I was able to get the rebuild kit from http://www.searspartsdirect.com

You will need a long Torx T20 driver if you don’t want to hack up your cover like I did.

You can find your Craftsman model number affixed to the side of your compressor. You type this model number into the web page and select search by model number. Then pick your rebuild kit which should come with the piston, cylinder sleeve and new rubber rings. Not all these bits may be bad on your compressor but if you’re taking it apart why not replace all the ware parts for one kit price.

Unplug your compressor, drain all the air and take off the plastic cover. I had a dog of a time with my plastic cover but you can watch the video if you want to hear more. Then remove the fill pipe.

This is the top of the cylinder head. The large side is the intake and the smaller side is the compression exhaust side.

Below is the top of the valve plate assembly and it is what controls the in/out of the air flow as the piston compresses the air. The valves open and close as air is sucked in and then compressed out into the tank.

And this is the bottom of the valve plate.